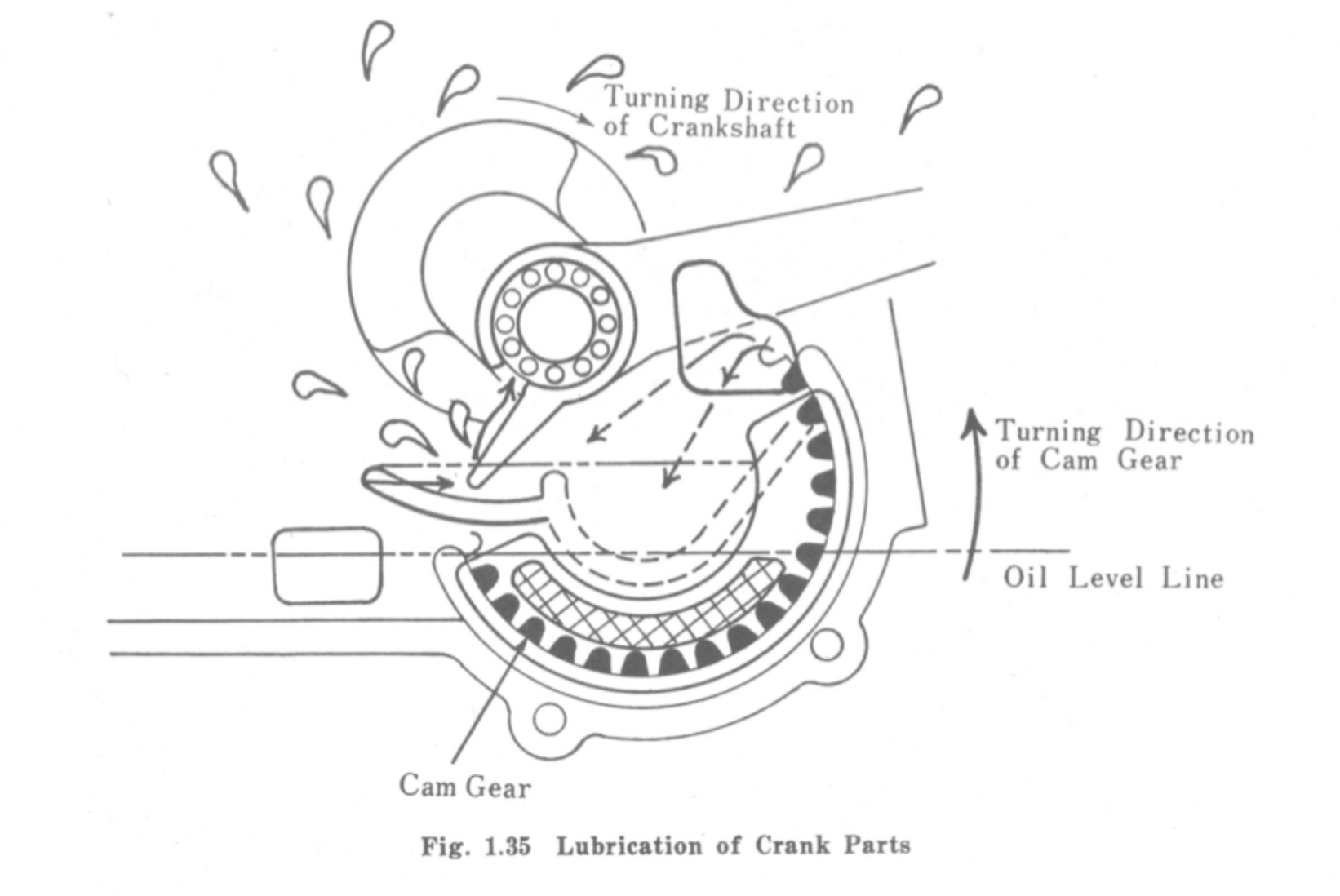

The first Super Cubs did not have pumped lubrication, instead the crank, piston and cylinder were splashed by oil thrown up by a dipper on the big end of the connecting rod.

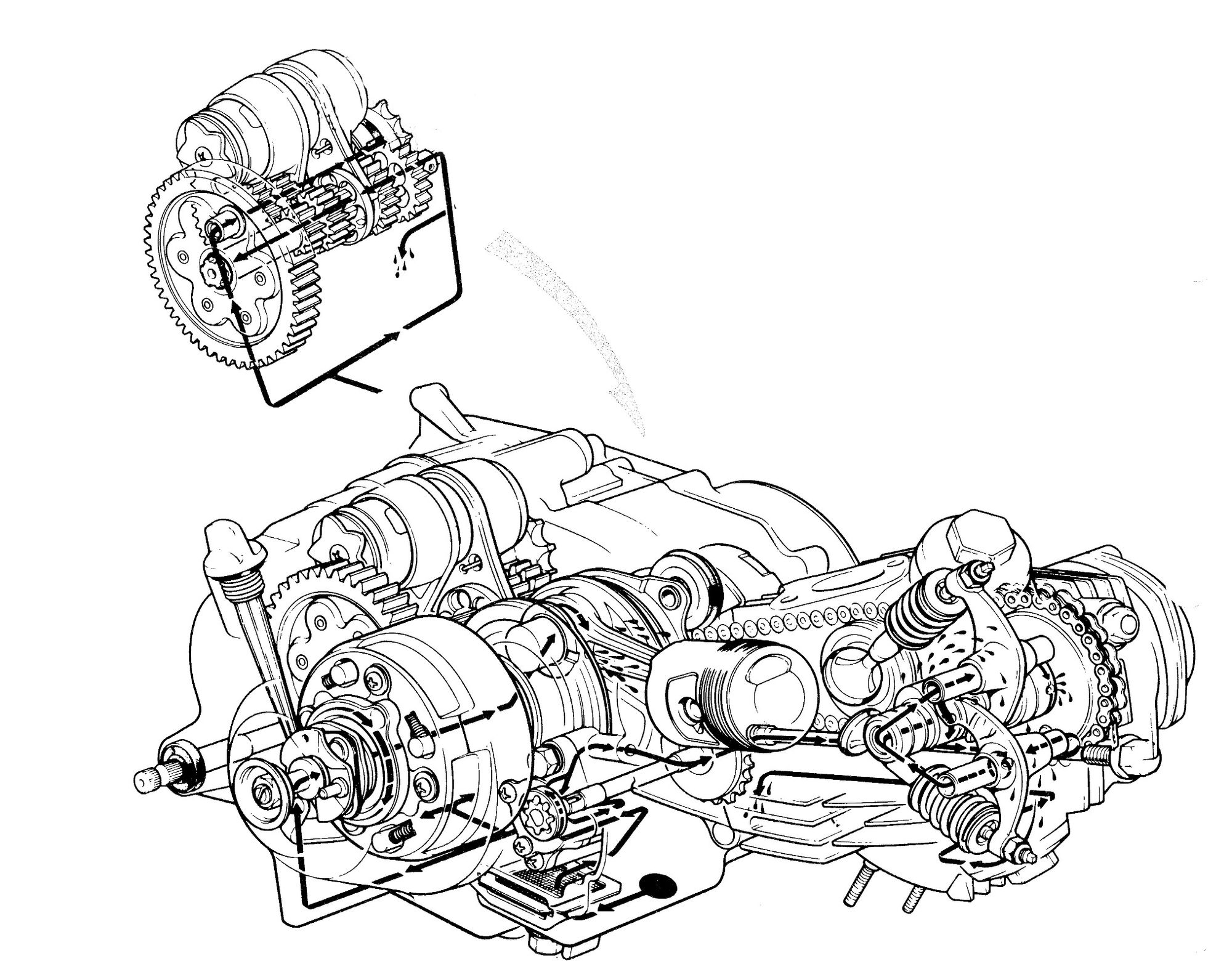

the ingenious 1958 C100 Super Cub lubrication system (left)/ connecting rod and dipper (right)

A similar device can be seen in towards the end of this excellent video about engine lubrication:

Chevrolet's brilliant introduction into engine lubrication (1937)

As shown in the diagram above, a cam mounted gear - which is below the crank in this piston-rod engine - acts like a bit like a waterwheel, lifting the oil from the sump before depositing it in a trough under the crankshaft where the dipper on the connecting rod scoops the oil towards the big end bearing and the underside of the piston.

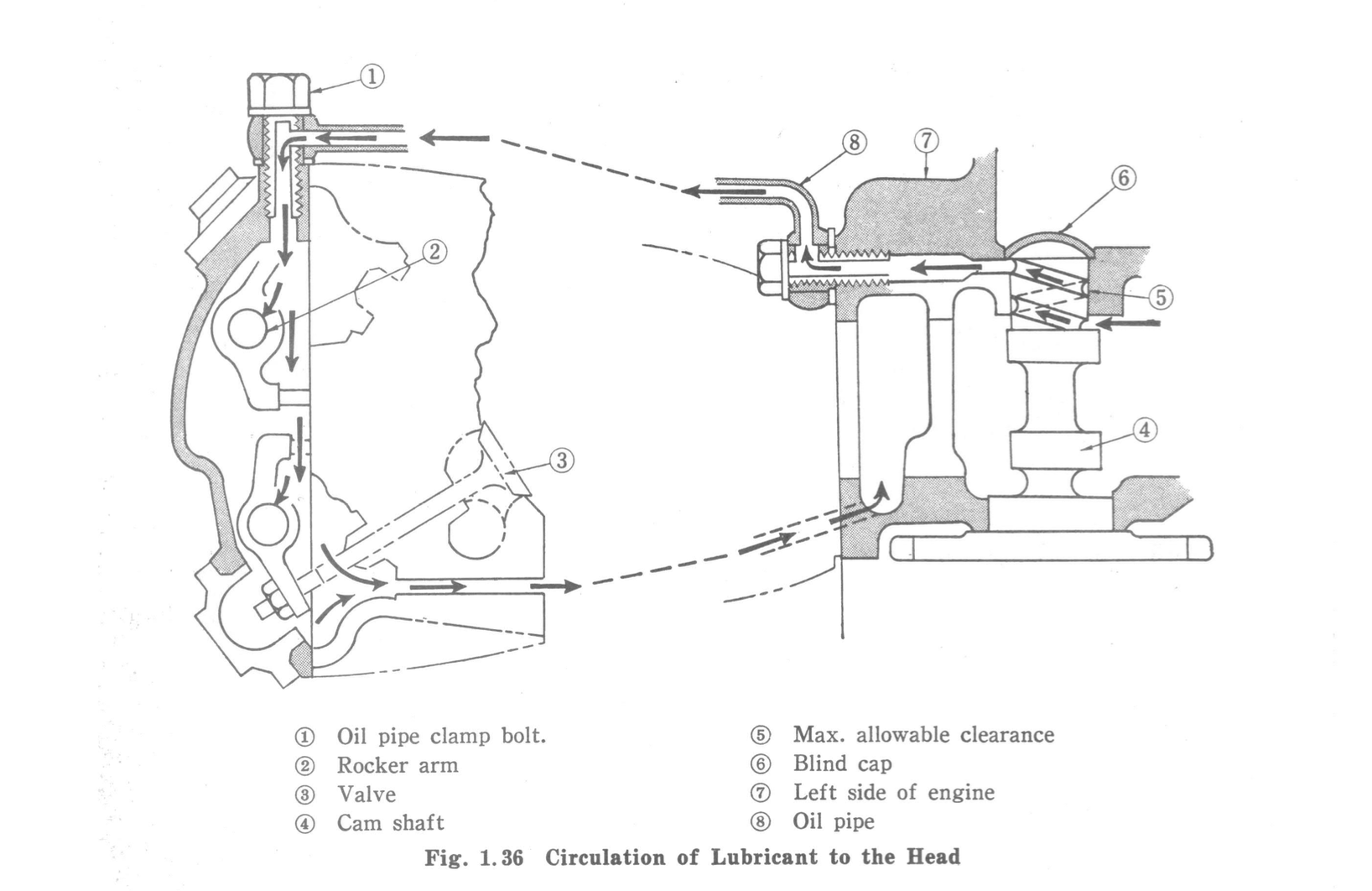

A screw shaped channel in the crankshaft bearing forces oil through an oil pipe to the head of the engine.

c100 lubrication to the head (left) / cam shaft with machined groove to move the oil to the head of the engine (right)

Pumped lubrication (1960s)

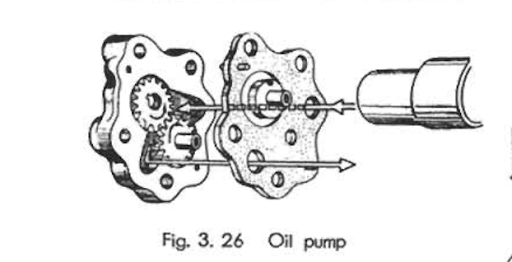

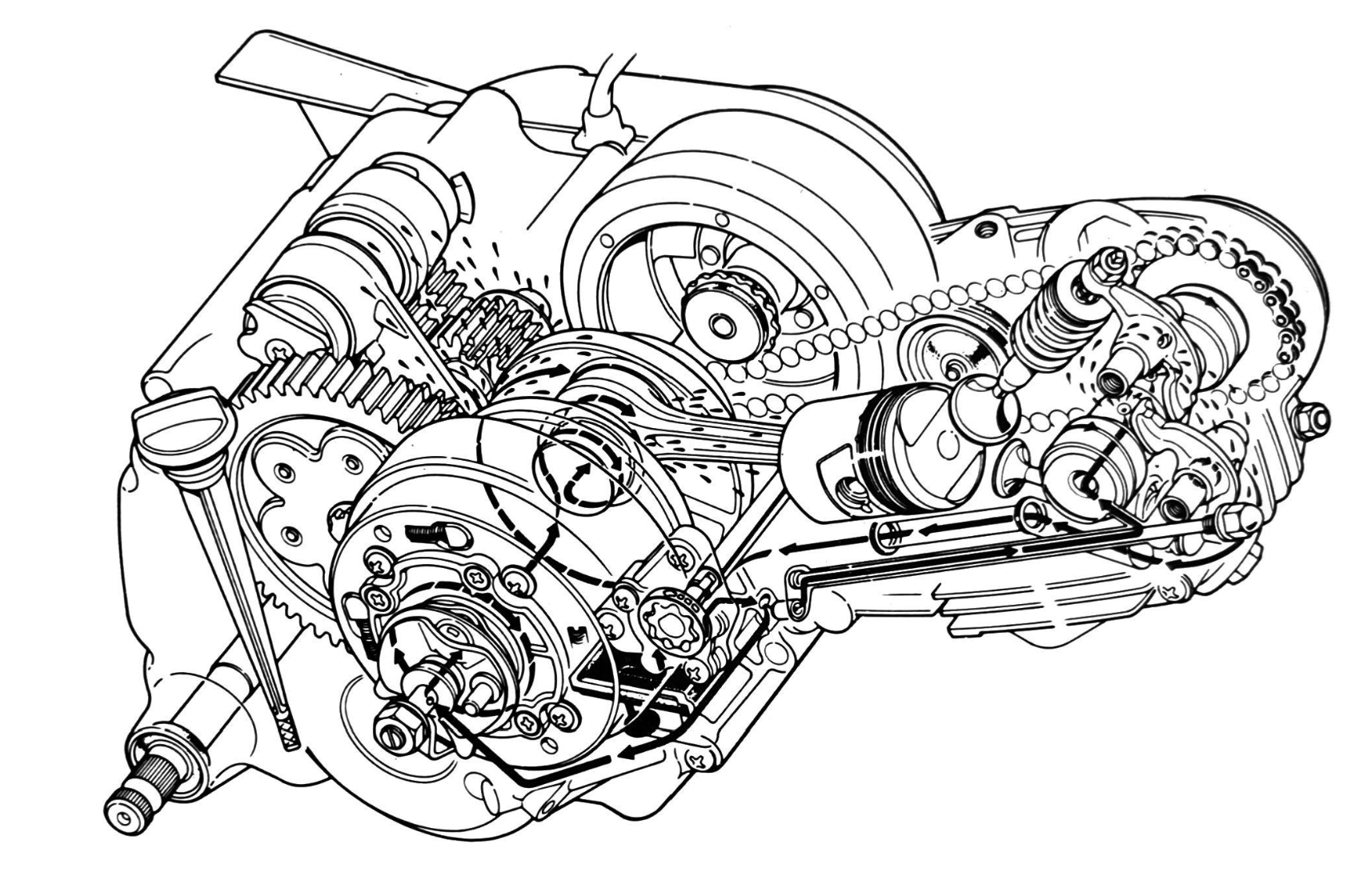

When Honda introduced their all-new overhead-cam engines in the mid 1960s they added a pumped lubrication system to improve the durability and longevity of engine components. The piston-based oil pumps Honda were using at the time in their larger twin cylinder motorbikes were too bulky for the very compact Super Cub engine so Honda devised a new type of low-profile pump. The earliest OHC engines came with a gear-type pump that used two gears to pump the oil around the engine:

piston pump from a 1962 Honda CA95 (left) / c90 gear driven oil pump used in the mid 60s (right)

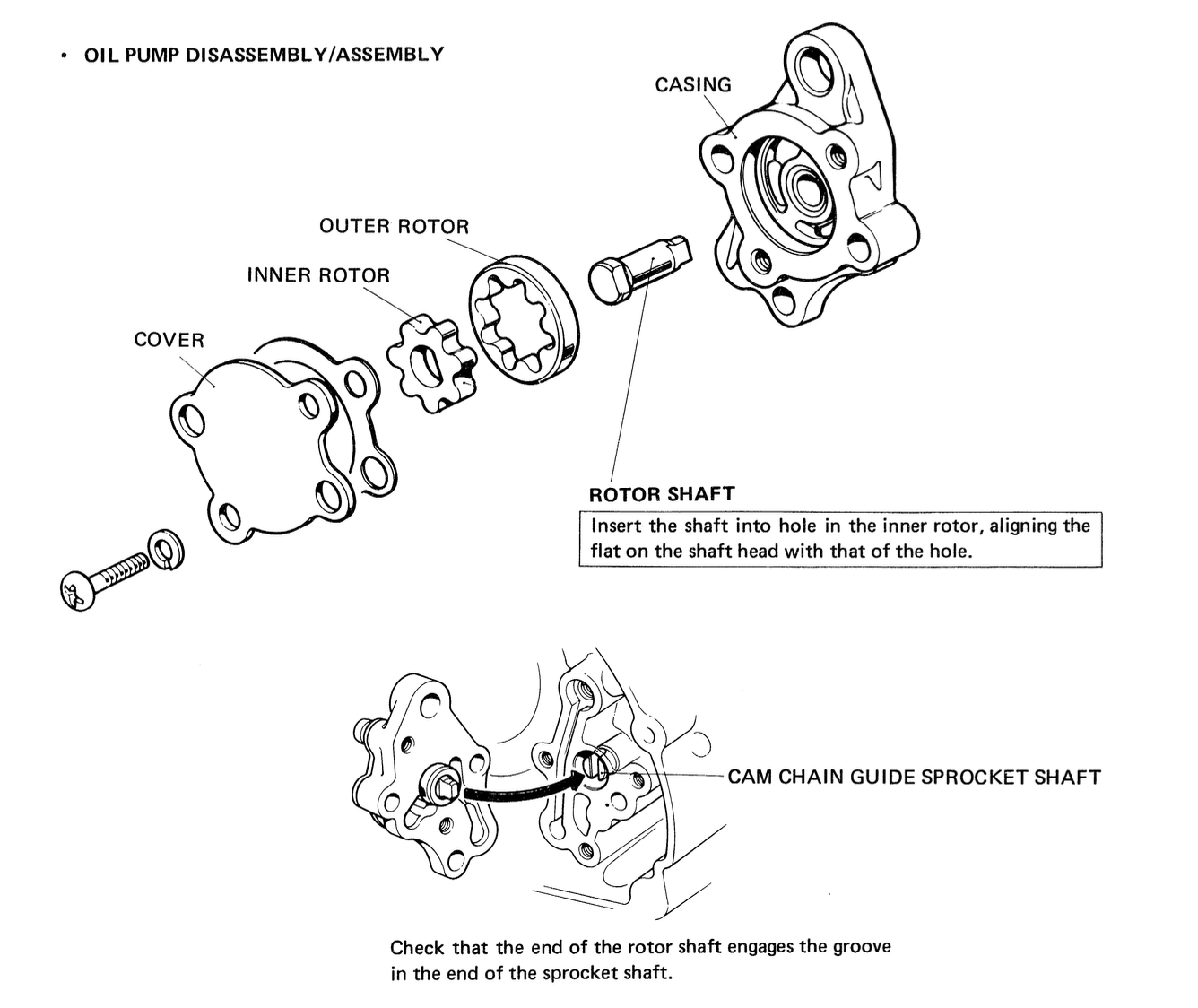

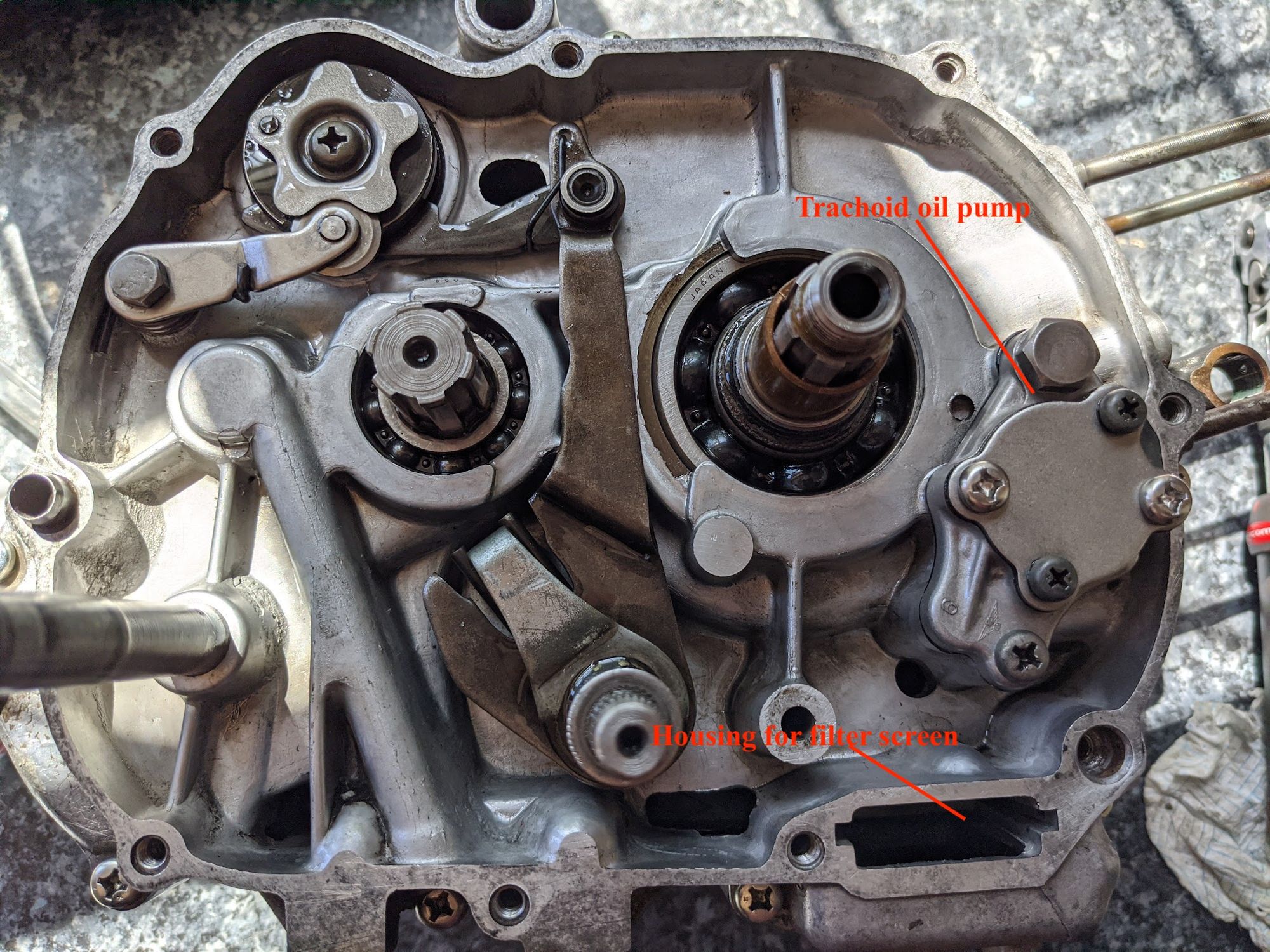

Shortly afterwards Honda introduced a smaller and more efficient 'trochoid' pump, which consists of an inner and outer rotor, the pumping action being produced by the different shape of the two rotors:

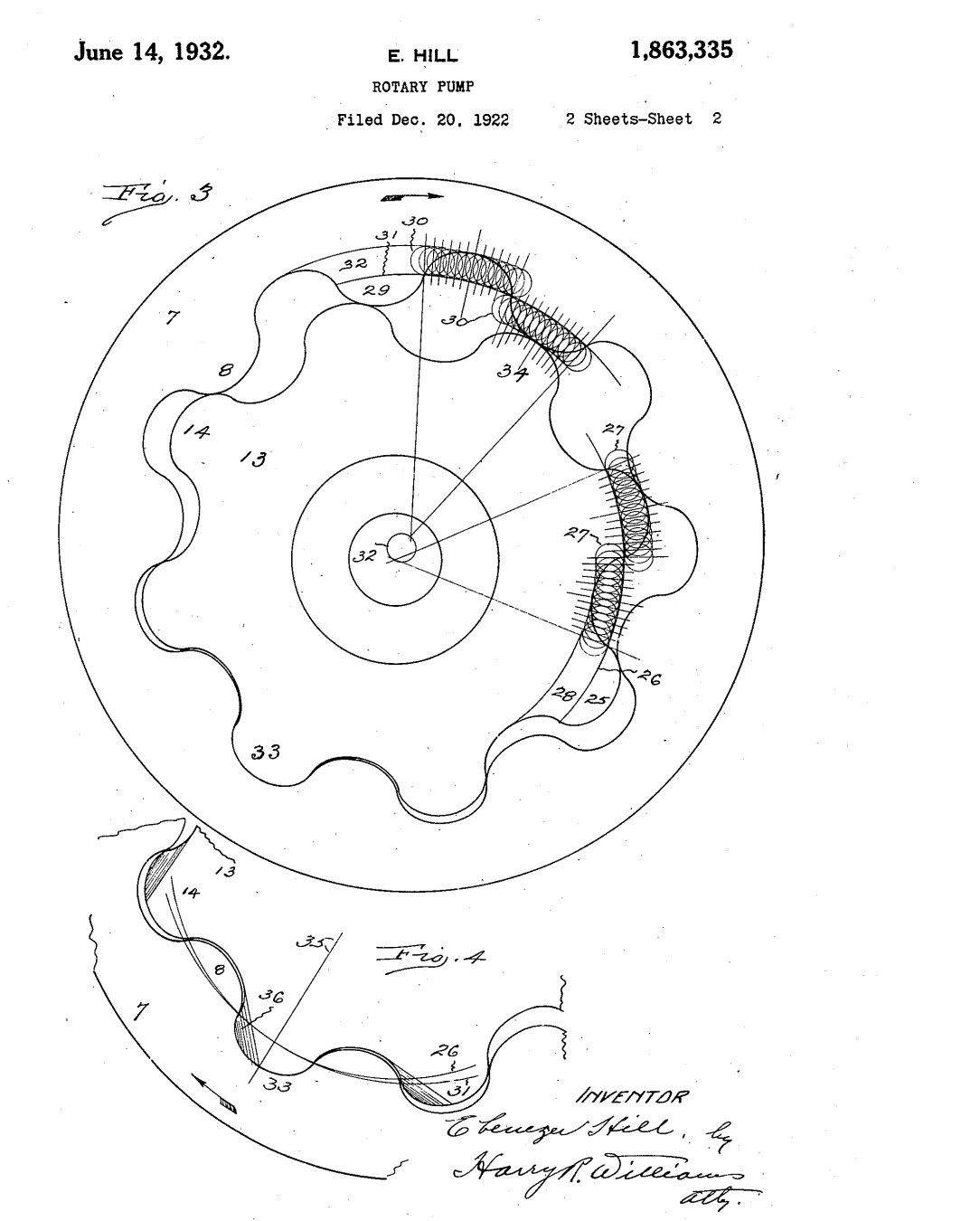

Trochoid pump operation (left) / This clever device appears to have been invented by the Edward Hill of the Hill Compressor & Pump Co in the 1920s

The c90z2 pump is shown below:

Oil filtration

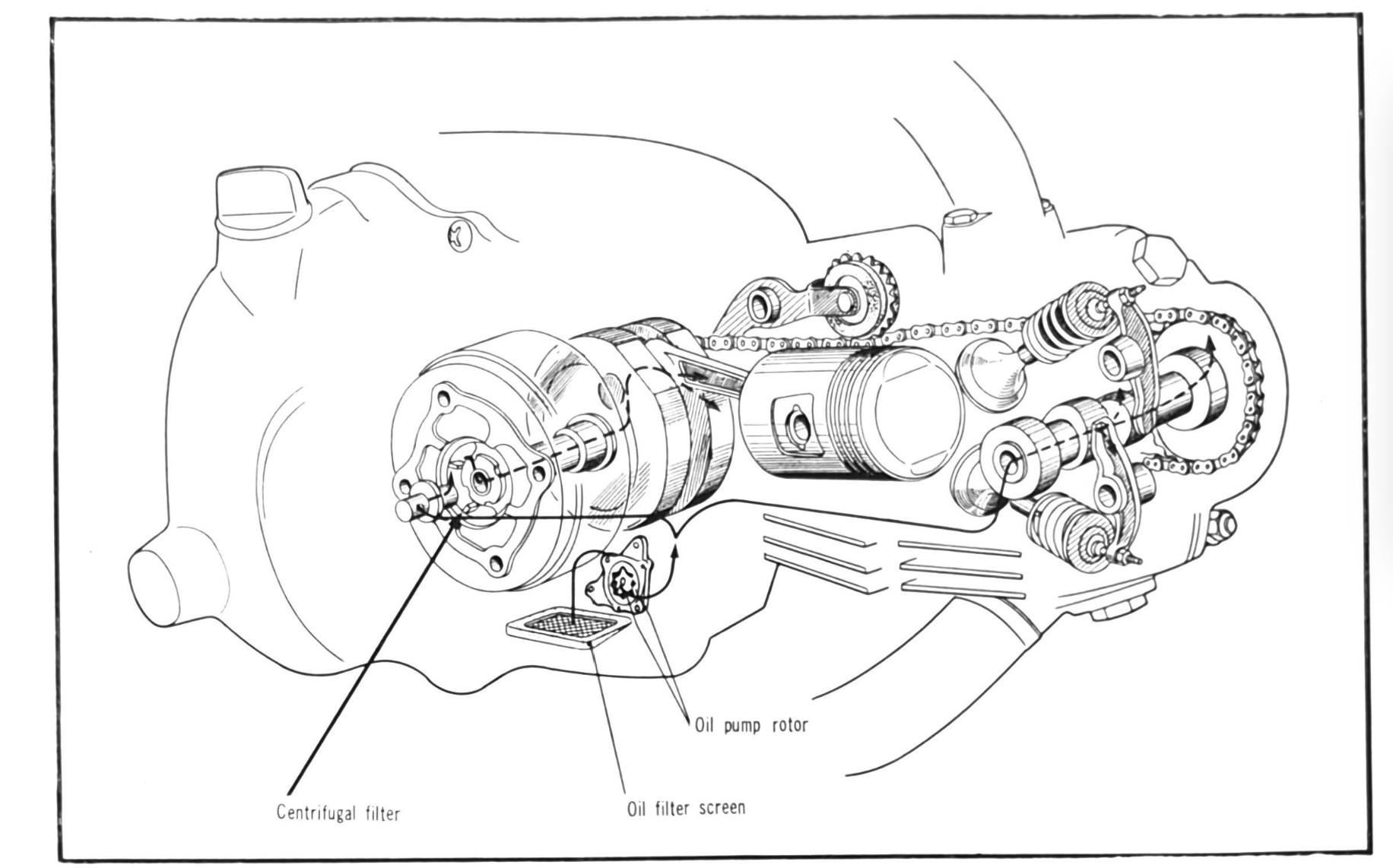

When Honda designed the automatic clutch for the Super Cub they incorporated a centrifugal oil spinner and this is the primary oil filtration mechanism used in the motorbike.

Oil enters the clutch from a passageway in the right crankcase and, because the clutch is spinning at thousands of revolutions per minute, the clutch acts as a centrifuge so that contaminants in the oil are flung outwards where they accumulate in the recess behind the clutch cover. Centrifugal filters are very effective[1] but they do need to be periodically cleaned to keep working properly. Unfortunately, unless the rider has read the owner's manual, they could be forgiven for not realising this was necessary.

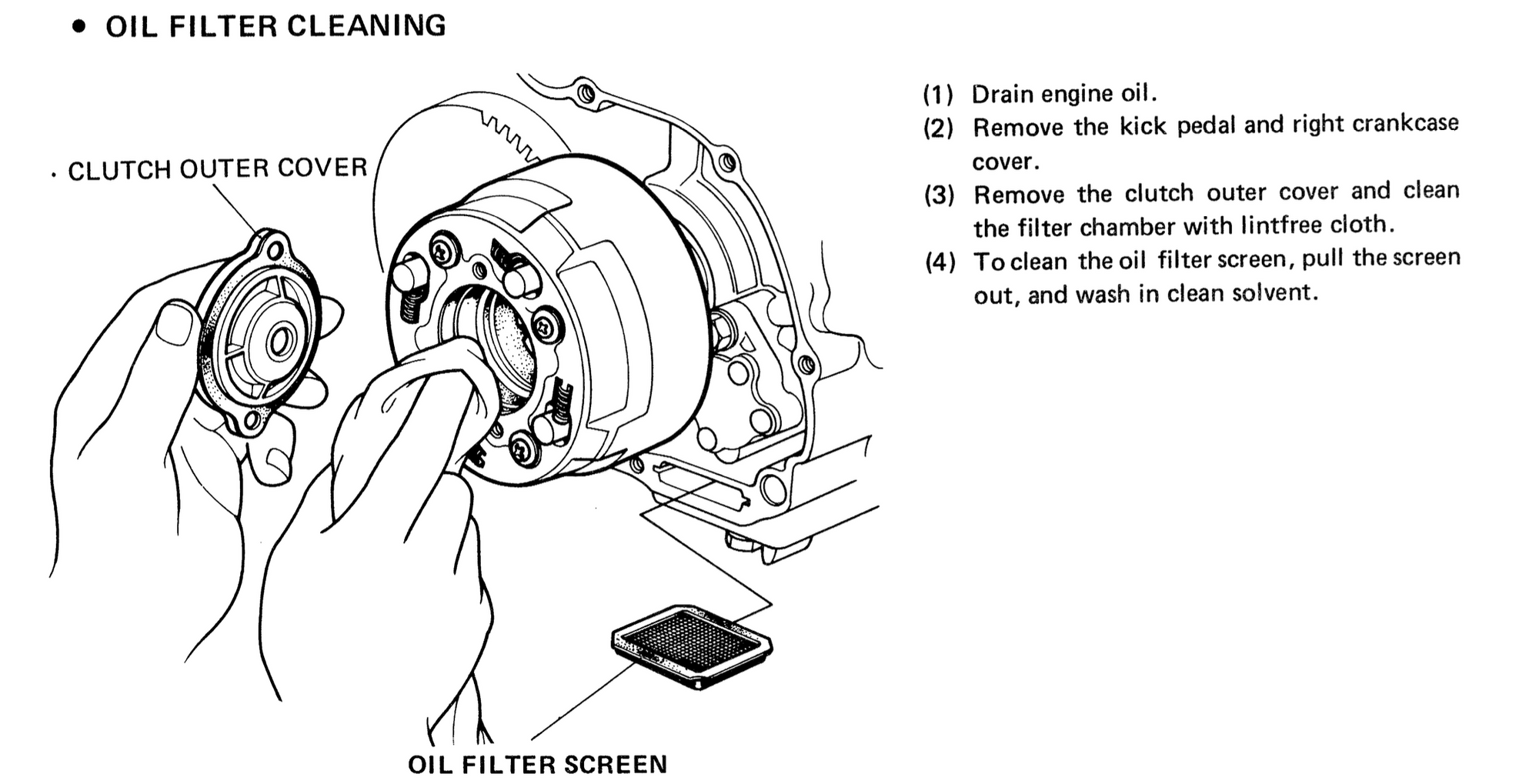

There is also a more obvious secondary filter in the form of a mesh screen that is installed under the oil pump. This acts as a basic strainer and helps prevent any large contaminants not yet caught in the centrifuge from blocking the pump and oil ways.

centrifugal filter and oil filter screen

Oil circulation

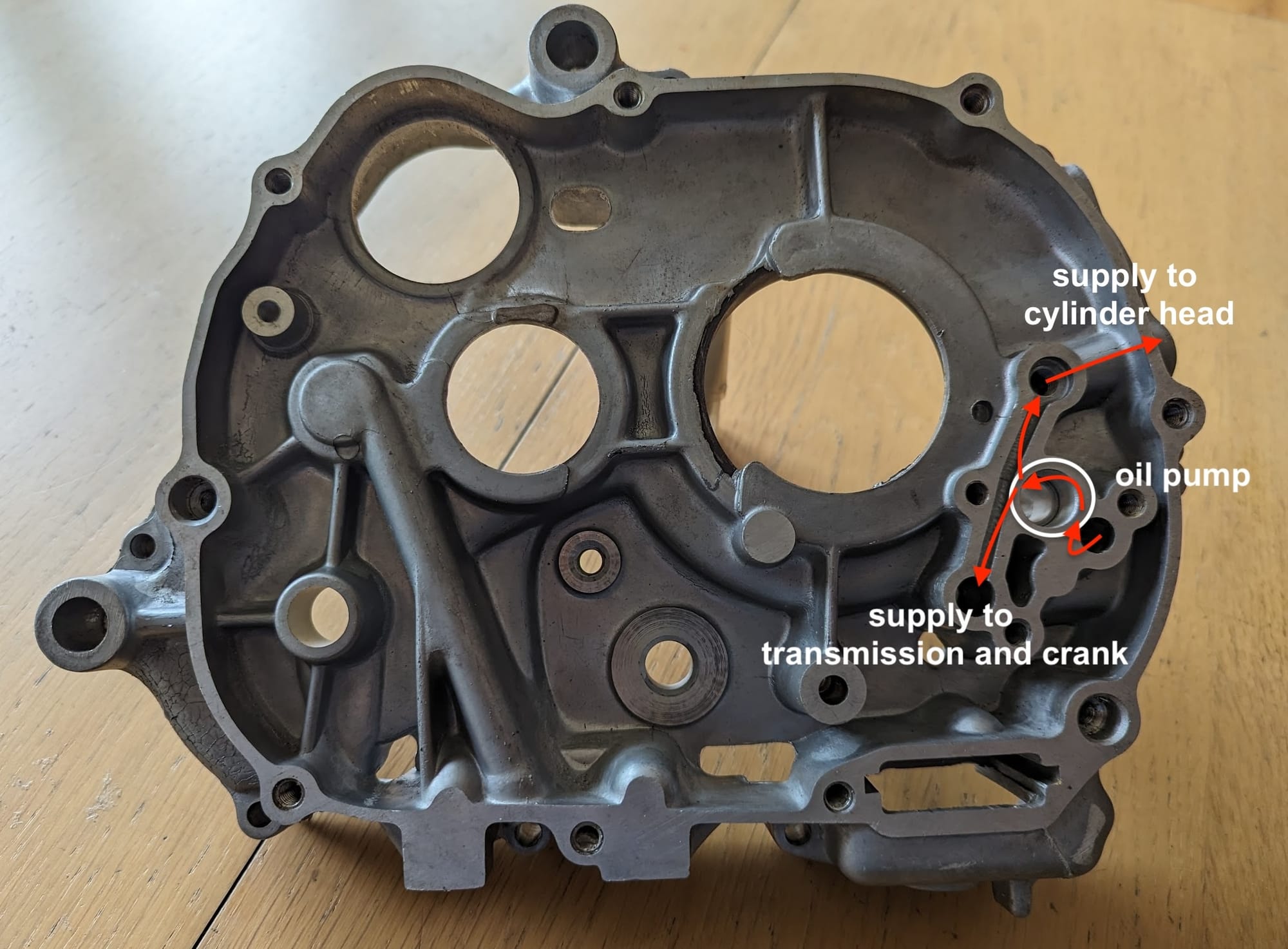

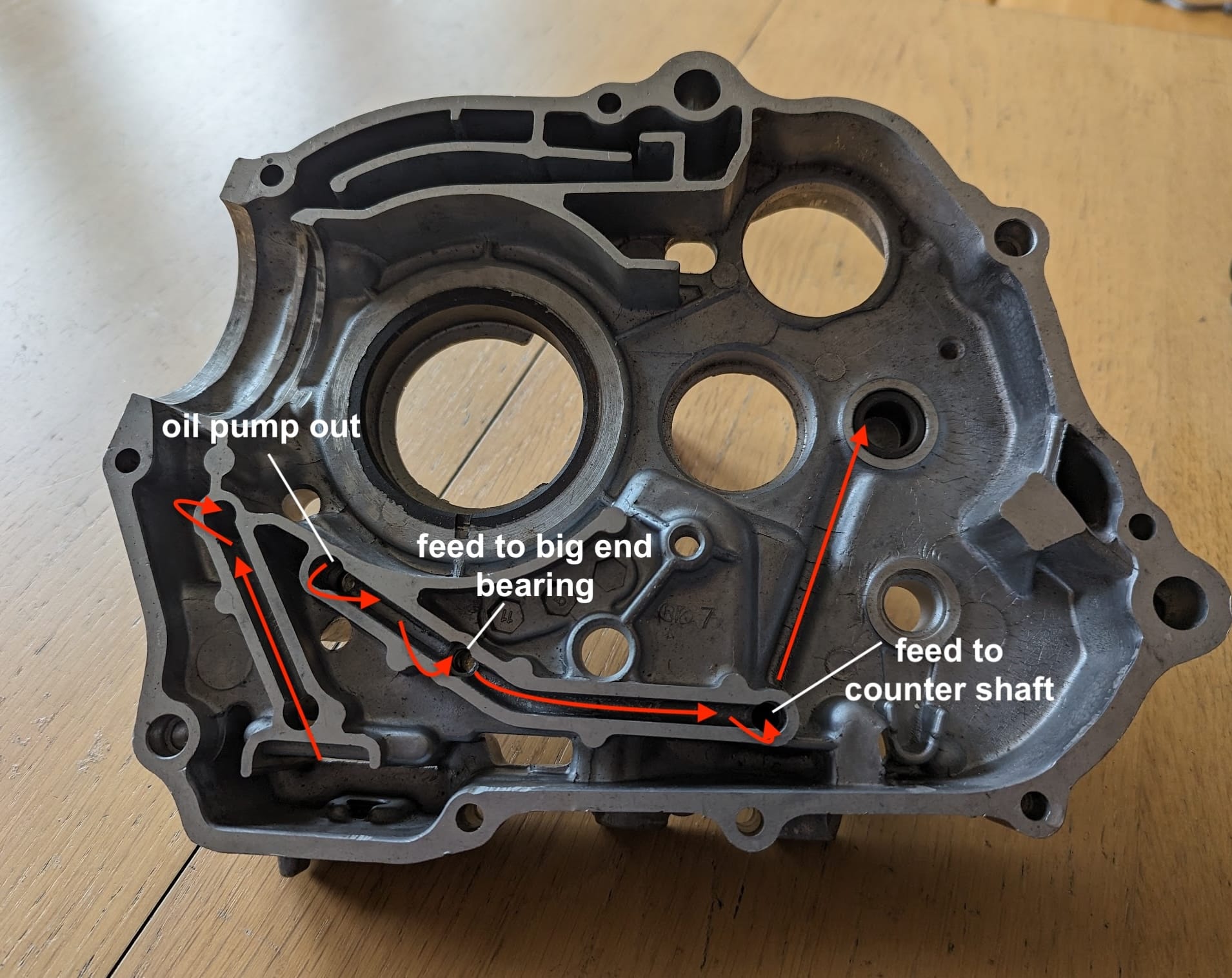

The lubrication path in the 89cc engine used in the 6v C90/CT90/CT110 bikes is shown below:

The oil is drawn up from the sump and passed through the filter screen where it is diverted in two directions:

- to the cylinder head via an oil feed gallery surrounding the bottom left cylinder stud[2]

- through a channel that runs to the bottom of the case and where it is further diverted:

- one path goes to the transmission where it is split again to lubricate the mainshaft and countershaft

- the other path goes through a channel in the right side cover to the crankshaft by way of the centrifugal oil filter in the clutch

(left) the oil pump is fitted to the right hand crank case / (right) the pumped oil goes into a channel on the reverse side of the case where it first feeds into a hole through to the right hand cover, supplying the big end bearing via the clutch. The next through-hole in the channel feeds both the counter shaft, via the galley shown, and also the main shaft via passageways in the left hand crank case.

The oil going via the cylinder head stud gallery goes into a channel in the camshaft where it lubricates the moving parts in the cylinder head. The oil drains back from the head to the sump via a hole at the lower end of the exhaust valve to the cam chain tunnel where it also lubricates the cam chain.

The oil entering the clutch goes on to the crankshaft where it is thrown out of the connecting rod big-end bearing, splashing the underside of the piston and the cylinder walls.

A simpler lubrication system was adopted in the newer 86cc 12v motor and the gears are lubricated by oil spray in the crankcase rather than via a separate pumped feed:

Lubrication problems

The 6v C90s have an unfortunate reputation for piston seizures and it has been suggested that the lubrication system is a possible culprit. According to this 1967 Honda service bulletin, over-heating is the primary cause of piston damage. The most common causes of over-heating are listed below:

A couple of the main causes of overheating are maintenance related: incorrect valve clearance and incorrect ignition timing.

Although not identified as a primary cause, the Honda Workshop manuals also mention lubrication issues as a factor in determining engine temperature:

The purpose of lubrication is to prevent direct surface to surface contact of the moving parts by providing a film of oil between the surfaces and there by, reducing friction and preventing wear. It also serves to cool the parts from the heat produced by friction.

As a result, when oil-flow is significantly reduced, say because the oil level is too low or because the volume of oil circulating is limited by blocked oil filters, then insufficient oil may be splashed from the big end to the cylinder walls to lubricate the piston causing it to overheat. With this in mind it is interesting to note that Honda upgraded the original oil pump fitted to the 6v c90s in the mid 1960s, suggesting that the early bikes may have had oil supply problems:

"The normal capacity of the oil pump is 1200cc /minute @ 4000 rpm ; if the capacity falls below 1000 cc, there is a danger of developing engine seizure, therefore, the pump should be repaired or replaced. (Trochoid pump : 1400 cc /min @ 8000 rpm)"

Honda 90 Shop Manual (1971)

In other words, the the original gear-driven pump was capable of pumping oil at the rate needed by the engine plus a 20% safety margin and the updated trochoid pump increased this margin to 40% (although the additional capacity is only achieved when the engine is running close to twice the RPM of the older design).

Are there some circumstances where the newer pump is still not up to the job? I've no idea, but some folk on the c90club forum have successfully upgraded their pumps to higher capacity versions and report lower engine temperatures as a result[3].

It is hard to be sure if the 6v C90s deserve their reputation for piston seizures. Given the length of time that Honda kept these engines in production it doesn't seem likely that there is an inherent design flaw that causes them to overheat. They do however all share a weakness in that they were all fitted to bikes that used contact breakers to determine when the spark plug fires and, per the Honda Service Bulletin above, when ignition timing is not adjusted properly this can result in overheating. Because the contact breakers wear over time they need regular checking and adjustment, a problem that was eliminated on the later 12v bikes which used a more modern CDI ignition.

Allowing for this, and the fact that the 6v bikes are now getting a bit long in the tooth[4] - which will have increased the opportunities for age-related mechanical failures - and it is not hard to believe that 6v do in fact tend to be the victim of heat related seizures more often than the newer 12v models.

Having said all that, it is worth reflecting that plenty of people run these bikes regularly without problems, and millions were sold. I suppose the key take-away should be that the old C90s were made at a time when owners were expected to do regular maintenance to keep them running well: you need to change your oil regularly, clean the oil filters, check your valve clearance and ignition timing and so on and so forth. All part of the fun of owning a vintage motorcycle!

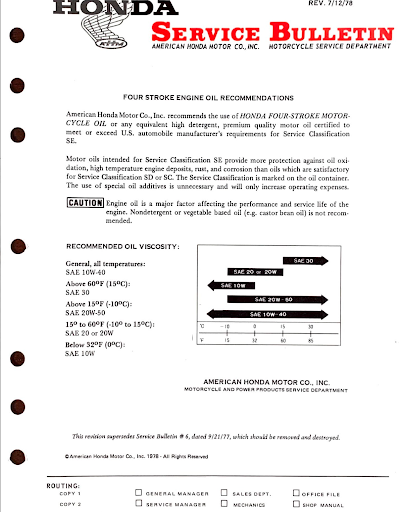

Oil type

Honda specify SAE 10W-40 as a suitable general purpose oil for all temperature conditions, although other oils viscosities can be used according to the average ambient temperatures of your area (see below). The jury is out on whether synthetic or mineral oil is best and Honda do not specify either way.

Some car engine oils contain additives that can cause the wet clutches typically used in motorcycle engines to slip. As a result in the late 1990s JASO, the Japanese Automotive Standards Organization, established a standard (called T903) that was optimised for motorcycles. The category of oil that is tested to perform well with four-stroke motorcycles that use a wet clutch is known as JASO MA[5] - you will see this printed somewhere on the specifications label of suitable oils.

Because the engine is high revving and does not hold much oil (just under a litre) it has to do a lot of work and Honda recommend it is replaced every 1500 miles[6].

that's it for lubrication!

References

| 1 | A centrifuge running at 6,000 rpm’s generates a force which is 2,000 times greater than gravity and these enormous forces are capable of separating out tiny particles (for instance clinical centrifuges spinning at less than this rate are capable of separating red blood cells from the plasma in blood).⏎ |

| 2 | because oil is pumped around the bottom left cylinder stud, this stud is secured with an acorn nut and a crushable copper washer to prevent oil leaks.⏎ |

| 3 | apparently a pre-1985 ATC125 pump will fit and has about 3x the capacity of the original (you will have to drill out the oilway going to the head if you do this upgrade)⏎ |

| 4 | even the last models in the 6v range, the Z2 and ZZ models, are now over 40 years old. ⏎ |

| 5 | there is also a category of JASO motorcycle oils called that are designed for 4 stroke scooters that use an automatic transition - these are called JASO MB oils. ⏎ |

| 6 | many owners prefer to do this even more frequently, say every 1000 miles, on the basis that oil is much cheaper than an engine rebuild! For similar reasons, some people prefer to slightly overfill their engines with oil to offset the oil used during long trips.⏎ |